A gyeplabda gazdag történelméhez hasonlóan az online kaszinók világa is saját történelmi mérföldkövekkel büszkélkedhet. Ha már itt tartunk, hadd mutassuk be Önnek a FatPirate online kaszinót, egy magával ragadó platformot, amely ikonikus szerepet tölt be az online szerencsejátékok világában. Népszerűsége egy legendás gyeplabda játékoséhoz hasonlítható, aki nyomot hagyott a szerencsejátékok világában.

Tesztelje szerencséjét és stratégiáját a FatPirate-en a https://kaszino-world.com/fatpirate/ oldalon, ahol a kaszinó szerelmesei izgalmas játékokban vehetnek részt. A FatPirate sokszínű kínálatával ugyanúgy meg akarja nyerni Önt, mint a The Hockey Museum lenyűgöző történetei. Itt teljesen új dimenzióban élvezheti a játék izgalmát.

It all started as a rumour from deepest Kuala Lumpur after the International Hockey Federation (FIH) World Cup in 1975. The Canadians as host to the forthcoming Olympic Games a year later were proposing to play the matches in one stadium on, of all things, artificial turf. The Asian world was not happy, regarding it as a western conspiracy to undermine their dominance of hockey on natural grass surfaces. Even the Dutch, Germans and the distant Australians and New Zealanders were alarmed at such a transition as none of them had invested to date in the dynamic polymer. Indeed, who was it that had done so?

The answer to that had been the Americans. Only one company, Monsanto out of St. Louis, Missouri, had seen the need a decade earlier to experiment with synthetic fibre manufacture to provide a sporting facility to combat harsh winters. The climate in northern latitudes of North America and Europe simply was the agent of deteriorating fields for hockey, soccer and American football. Grass was vulnerable.

The technical response was the production of new uniform synthetic yarns to feed the tufting and knitting machines to produce the first AstroTurf nylons in response to the demands of a new sporting market. The Canadians in planning for the 1976 Games had installed an artificial surface at the Old Empire stadium in Vancouver, which had been well received by players and national and international officials alike. This potential was replicated by the FIH encouraging a pre-Olympic tournament at McGill University in the summer of 1975.

Ed Milner was head of Monsanto‘s product development working alongside the international body who had recognised early challenges of drainage, the shock absorption and the effects of traction on the players’ ability to twist and turn at high speeds. Once introduced to field hockey, he commented even more on its effect on ball movement.

“We really had our work cut out on directional fibre; the nap of the carpet caused a two-directional variation in the run of the ball’s interaction with the surface”.

The ball transition was smooth in one direction but bumpier travelling the other way. At the pre-Olympic tournament in 1975 a host of international players were reporting that the surface was so hot in the summer sun that the soles of their playing shoes were melting! The vital breakpoint in the development of hockey from a dry-play sport occurred after a game between Kenya and Mexico was interrupted by an extreme thunderstorm. When the skies cleared, the play resumed with not just a cooling effect on the surface, but also with the advent of a smooth and fast passage of the ball. The competitors could rely on regular and predictable behaviour of the ball at last, fast and true. Astroturf hockey was born on water!

Denys Cooper, the Canadian secretary, was to set the scene for decades to come in his collaboration with Rene Frank, the FIH President. He highlighted the problem then and there of water, more water and how much at the top table of tournaments? In response, Ed Milner hastened the process of texturisation of the fibres to produce a softer feel to the grass which had once been described by a prominent player as a green Brillo pad – an abrasive scouring brush for pots and pans!

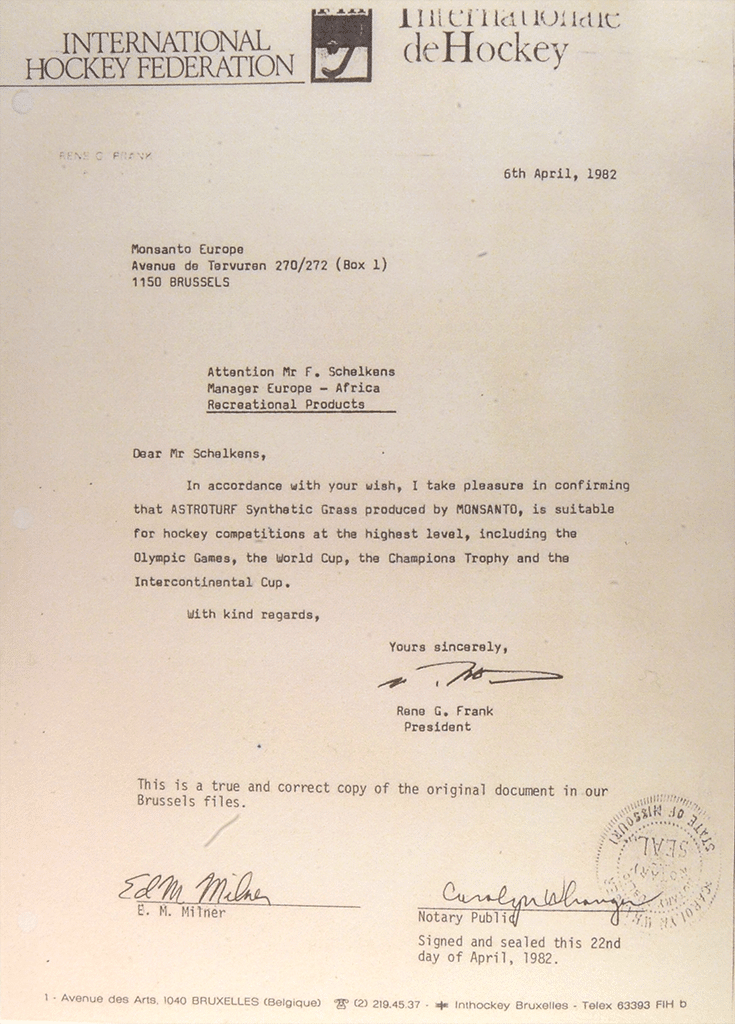

Letter from FIH President Rene Frank to US company Monsanto, the original creators of AstroTurf, confirming their surface suitable for elite hockey competitions. Letter dated April 1982.

What was it like to play at the 1976 Games in these early years of transition? Would the introduction of turf impact on new skills and styles of play? Early results would seem to have favoured the attacking philosophies of teams like the Netherlands, Australia and Pakistan who were able to pile up high goal-scoring rates. Rapid ball transfer, one-touch passes and deflection skills gave attackers more options whilst defenders had to make their tackles and interceptions count as the recovery process of turning was a challenge to their mobility.

Hockey had immediately become a more mobile game with more emphasis on movement, uninterrupted runs off the ball to receive passes whilst at the same time enhancing the dextrous hand-eye abilities of dribbling skills. Once a non-directional pile and the manufacture of specialised Adidas and Converse astroshoes were introduced, the attraction of hockey was off and running as a far more appealing sport for the player, the spectator and its potential coverage on television.

After a century of hockey on grass in all five continents, the 1970s was the decade of the sport’s dynamic revolution. From Montreal onwards, revolution would give way to evolution as the gurus of turf like Ed Milner along with the game’s governing body, the FIH, would be intent on spreading the sport on artificial surfaces to a modern and demanding worldwide playing population and audience.

If the dawn of Astroturf’s birth had been American, the hockey core of European nations had not been standing still. The sleeping carpet belt running from the Netherlands through Belgium into Northern France was to abruptly awaken after 1982 with the FIH’s formal recognition of the AstroTurf brand as a hockey leader. Now the real battle for competition in synthetic turf would begin!

It was all a matter of technology and cost. The Netherlands had been built from reclamation and sand. The 1980s would see Dutch companies expand their engineering base of sand technology into the vital infill of polypropylene carpets. Desso along with Edel Grass and their constituent supplier of yarn, Ten Cate, entered the market very much buoyed along by the rapidly developing hockey club populations and the success of all their national teams in world events. Then there was the cost factor. Clubs, schools and colleges just couldn’t afford the Rolls Royce price of AstroTurf’s nylon so despite its proven player-friendly qualities, they would turn to Desso’s early flagship ‘Sportilux’ carpet at half the price. The choice was Rolls Royce or Mini Cooper!

A Desso synthetic grass promotional catalogue.

The advantages were initially clear-cut for these surfaces of tightly packed fibre, not with water but sand infill all underlain by what was then described as a dynamic base of layers of graded stone with only a geotextile layer separating the stone from the carpet. The early few years of play afforded a very acceptable level of quality of performance. Almost replicating the nylon surfaces’ ball roll and speed, the polypropylene soon displayed susceptibilities during heavy use, notably when applied to multi-sport concentration. One was the compaction of the fibre which resulted in differential ball speeds and inconsistency of performance between dry and wet conditions. The other perhaps was more daunting! With tighter government controls of health and safety in the developed world, these sand-filled ‘dynamic surfaces’ held no absorption to the stresses on the body. In short, there was no support for the body. Engineered bases had to be supplied in order to prevent chronic skeletal injury. It was at this juncture that the German rubber industrial sector stepped in to provide a variety of shock-pad systems to underlie the carpet layer. Balsam AG in Germany and Desso in its merger with Deutsche Linoleum both forged ahead in offering hockey facilities and pitch performance that could endure a decade’s heavy use with a higher quality of match-play performance.

An example of a mid-1990s sand-dressed synthetic turf, a more affordable option for European hockey clubs and schools.

Yet, the evolution of hockey turf was still in its infancy. With the widespread use of engineered bases, attention turned to the rubber element of shock pads and their resin content and more significantly on their effects on ball bounce and rebound.

Yes, they would provide comfort underfoot but would they also have a trampoline effect on excessive ball bounce with the hockey player losing confidence in an inconsistent ball roll?

The FIH had to step in by this stage and engage with worldwide laboratories that would provide stringent tests on the cushioning properties and the vital elements of ball to surface behaviour of roll, speed and deviation. As the 1990s progressed these Test Houses were to play a more prominent role in both standardising but also innovating potential new pitch systems for the clients’ satisfaction in the future.

The 1990s saw the industry listen to the players’ concerns and aspirations. Inevitably they required the performance of a wet nylon surface with its underfoot comfort but at the cost of their local field’s sand-filled polypropylene. Impossible surely? Scientific application was busy in the labs of the ‘carpet belt’ yet again. Worldwide, the hockey family wanted a softer product, dense in its constituent make up but hardy enough to maintain high-quality playing characteristics over a longer period of intense play. So was born the polyethylene fibre for hockey.

With parallel research in the Netherlands undergoing similar innovation, the French company Tarkett forged ahead with the early polyethylene surfaces in acknowledging their suitability for water and sand infill and for their equal compatibility for hockey and football. The company provided clear evidence of the way forward by constructing full-field training facilities at their football academy at Clairefontein close to Paris in preparation for the World Cup-winning football team of France in 1998. Very, very rapidly the Test Houses and FIH equipment committees would view the product, test it and soon enough pronounce its suitability for all levels of hockey. Polyethylene was born in the 1990s but was fit for the expansion of the sport in the twenty first century.

The elite olive-green, water-based AstroTurf surface at the Atlanta 1996 Olympic Games.

Synthetic turf’s widespread availability on a global scale was soon to be fully implemented on a much more integrated level. Until 2000 a great deal of the technical progression in sports like hockey was formed on the basis of empirical evidence from those practitioners at the coal face, the players, the coaches and the umpires. This applied to their preferences on surface type as well. Their contributions were augmented by the findings and conclusions of a small number of Test Houses like MSC in London, Sports Labs in Scotland and Labosport in France.

To date they were relying on authentic but limited base testing on traction and ball bounce.

This was soon to change as powerful new players and processes would emerge in the form of national governing bodies (NGBs) with their own required agendas. These were to be very influenced by the dictats of government and the International Federation responsible for the sport’s wellbeing. Health and safety became primary concerns along with an increasing awareness of the environmental impact of ‘plastic pitches’ on land use and that old but recurring chestnut of water conservation. Empirical sport-based, hockey-centric advice was to be replaced by the necessity to test hockey fields on broad fronts of performance, suitability for specific sports and most evidently for safety concerns.

The Test Houses inevitably responded with more advanced technology with the scope of their endeavours almost endless in their intensity and variety. New equipment was patented for ball roll machinery with more detailed measurements for requirements and conclusions to be made on hydrophilic fibre and UV stabilisation. The inevitable results forced labs into more research and development and the need for financial and professional expansion.

A notable consequence for original sports engineering consultants like Sports Labs was the change in their income stream. In 1999 they recorded 85% of their income was derived from consultancies and guidance for potential purchases of facilities. By the end of the first decade in business, this was reversed with pitch testing accounting for nearly 90% of their input and income.

It was not only the Test Houses who experienced rapid change. The abundance of turf providers and yarn manufacturers were to be subject to the global effectiveness of consolidation and acquisition. For any one hockey facility the client would have to meet the rising costs of the research and Test House development along with the advanced technology of the industry. Fencing and floodlighting prices alone were spiralling adding to every budget. Synthetic turf provision had become global with associated fuel and transport costs; in short, it was now a capital intensive business.

Many companies ceased to trade or took the choice to provide a smaller derivative role in the process. The agglomerated groups had been waiting for their day, and over the last two decades up to the FIH’s centenary in 2024, a small number of survivors dominated the world business. Polytan has spread its wings to acquire the AstroTurf nylon empire whilst simultaneously expanding its polygrasse systems for both sand and water across the globe.

Cosmetically the company was also to introduce coloured playing surfaces with an option of differential coloured run-offs. A deep blue for the main pitch area became ubiquitous at many levels of hockey, but with televised hockey, it became a pre- requisite. The background blue surface did make the ball more visible to the viewer. It became trendy to have blue installed!

The blue Polytan pitch with pink run-off laid for the London 2012 Olympic Games.

The owners of Polytan, the powerful Sport Group in Germany, have equally sought after high rolling partners across the financial and commercial sector. Hockey-wise they have forged partnerships and sponsorships with the FIH and its Olympic credentials but also they have been at the forefront of determining new advances in playing surfaces since the advent of 3G (third-generation synthetic surfaces) in 2000. Its quest for environmentally friendly fields is paramount!

The third generation of pitch development with its emphasis on longer pile of 50-80 mm in fibre height has been a classic example of how turf providers have worked hand-in-glove with the NGBs, the FIH and the Test Houses to provide options for hockey clubs and educational sites. In the end, the rubber crumb infill was rejected by the world hockey community but the sand-dressed, multiple-use small play areas were to prove very popular for city areas in particular. Rubber was too slow but the multi-use games area (MUGA) proved resilient.

The modern hockey follower demanded speed and consistency of ball roll and behaviour; companies liked Edel and Greenfields in the Netherlands have thrived in a shrinking number of competitors. Polytan and its provision of a one-stop shop has dominated the world hunger for synthetic surfaces. Nevertheless, this concentration of technology in north-western Europe has also reared problems for the FIH as all the competitional, medical, coaching and technical assets have resulted in world dominance in match-play for the Netherlands, Belgium, Germany and Great Britain. The FIH has inadvertently been left with the haves and have-nots as World and Olympic medals are the property of the few, the same few!

This dichotomy applies even more to their insistence on water-filled systems for international hockey. To date, all World, European and Olympic competitions have been held on water. Under-developed nations have been short of water for decades and crying out for assistance from the world governing body. The FIH has responded with its intent to encourage dry-play surfaces for the future. Indeed, in 2023 and 2024 under-exposed hockey nations like Uruguay, Oman and Namibia were to qualify for the Finals of a Hockey 5s competition on a dry-play surface in Muscat, Oman. This development must be applauded.

However, how ironic that the hockey world has come full circle from the Kenya and Mexico match on the dry play AstroTurf of 1975. Then, as now, in Canada to Oman, the players involved from all the competing nations have given their feedback to the FIH.

In Muscat every team with good supportive crowds enjoyed the event. Nevertheless, the players still did not enjoy the resistance of the surface to dragging the ball at Penalty Corners. The ‘feel’ was just not there. They complained about the lack of stability on foot hold and transfer on the dry surface; they were sliding.

After all these years with experimentation on dry turf, the jury is still out! The players have yet to be convinced!

© Gavin Featherstone

Epilogue

This article on artificial turf was written by double Olympic coach (USA and South Africa) Gavin Featherstone in July 2024 for the International Hockey Federation (FIH) – part of The Hockey Museum’s contribution towards the FIH’s centennial book. The Hockey Museum has chosen to publish Gavin’s article in its original, unedited form, with the permission of Gavin and the FIH.